ADVERTISEMENTS:

In this article we will discuss about the eight methods used for harvesting water.

Method # 1. Negarim Microcatchment:

The word Negarim is derived from the Hebrew word which meaning is the runoff. And at the term Negarim, the Negarim micro-catchment has been devised as a well-known water harvesting system. Shape of this micro-catchment is like diamond; and is surrounded by small earthen bund. There is an infiltration pit at the lowest corner of micro catchment. The function of infiltration pit is to collect runoff generated within the basin.

ADVERTISEMENTS:

Such micro catchments can be used for growing trees or bushes. This technique is found very suitable for small-scale tree planting in any area suffering from moisture deficit. As benefit, this system harvests the water for the trees, along with conserving the soil. This system is very simple in its construction; and does not involve more money expenditure.

In Israel there is large number of well-developed Negarim micro-catchments, in the Negev Desert, where rainfall is as low as 100-150 mm per annum. Similarly, by making little modifications, this technology is widely in use, in several other semi-arid and arid areas, especially in North and Sub-Saharan Africa; and also in several other countries.

The micro catchments can be constructed as single and open-ended structure in “V” or semi-circular shape. This offers advantage of outflow of excess water from around the tips of bund; however, its storage capacity is less as compared to the closed end system. The open-ended bunds are suitable for broken terrain, and when small number of trees are required to plant around homesteads.

Catchment Size:

ADVERTISEMENTS:

The size of catchment is determined on the basis of tree/plant water requirement. However, the size of micro-catchment (per unit) normally varies between 10 and 100 sqm, depending on the tree/plant species to be planted. A larger size of micro catchment is desirable, especially when more than one trees are planted within one unit.

Bund’s Specification:

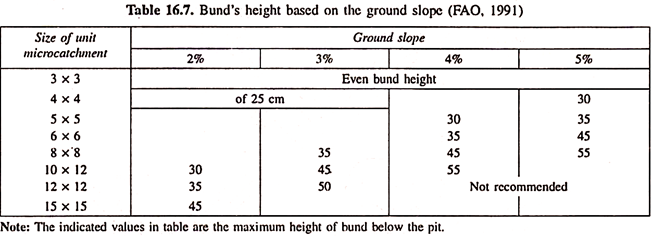

The bund height is decided on the basis of ground slope and selected size of micro-catchment. However, as per recommendation the bund’s height should be at least 25 cm to avoid the risk of overtopping of excess runoff and subsequent damage. As a precautionary measure, when ground slope is more than 2.0%, then bund height adjacent to infiltration pit must be kept more.

ADVERTISEMENTS:

The height of bund, based on the ground slope is presented in Table 16.7. The top width of bund should be at least 25 cm; and side slopes should be in the range of 1:1 to reduce the soil erosion during rainfall. For protecting the bund section, the bund should be covered with grass cover.

Specification of Infiltration Pit:

The maximum depth of infiltration pit should not be more than 40cm. If it is more than this value, then there is possibility of water loss through deep percolation; and also there is greater earthwork, which makes the construction more costly. The recommended values of infiltration pit dimension are cited in Table 16.8. In order to better utilize the excavated soil materials, they should be used for constructing the bund around the infiltration pit. The earthwork involved under construction affects the input cost.

Attempt should always be for reducing the earthwork. The quantity of earthwork required under different layouts of the system is presented in Table 16.8. The earthwork per unit micro-catchment includes only of the infiltration pit and two side bunds of the catchment, while the earthworks of other two bunds are included in the u/s micro-catchment. If diversion ditch is required, then an additional earthwork at the rate of 62.5 m3 per 100m length of ditch should also be included in the total earthwork.

It is accomplished under following steps:

ADVERTISEMENTS:

Step 1:

The first step is to determine the position of contour line. It can be done with the help of level or a water lube level. Before arriving at the final position of contour line the uneven surfaces should be smoothened so that finally a uniform soil surface is obtained. The first contour line should be marked at the top of the block. If the land topography is very uneven, then separate small blocks of micro catchments should be considered.

Step 2:

Mark the tips of bunds along the straightened contour. The first line of bund should be in open- ended form. The distance between the tips depends on the catchment size, presented in Table 16.9.

Step 3:

Take two pieces of string for the length equal to the side of catchment, i.e. if the catchment size is 25 sqm (5 m x 5 m) then length of side or string will be 5 m. Hold one string at one tip (i.e. at x) and the other string at the other tip (y) which will exactly meet at the apex point z. The point z is marked with a peg; and the catchment sides (x-z) and (y-z) are marked on the ground surface. This procedure is repeated until the positions of all the bunds have been demarcated.

Step 4:

Slake the next row of micro catchment. For deciding the position of next row catchment, the apexes of the bunds of the upper row should be taken as the tips for the second row; and the corresponding apex is determined according to the step-3. After deciding the position of second row catchment, repeat the same procedure for locating the third row, and so on for the others. The last block is kept in the diamond-shape micro catchments, with first row, open at the upslope end.

Step 5:

Demarcate the size of infiltration pit based on the Table 16.8; and excavate the soil by leaving a mall step towards back for planting the seedling.

Step 6:

Clean the area within the micro catchments before going for construction of bunds. The bunds should be constructed in two layers by using the excavated materials from the pit. For better construction, the soil should be compacted very well during construction.

The soil should be wetted if moisture content in the dug soil is not in proper range. The compaction may be done with the help of suitable means. Also, for ensuring a uniform height of bund, a string should be fixed at the beginning and the end of each bund alignment; and accordingly filling or removing of the soil is carried out as per deflection in the string.

Step 7:

If there is risk of damage due to huge runoff, then there should have the provision of diversion ditch. The diversion ditch should be located above the block of micro catchments. The alignment of diversion ditch should be at 0.25% slope. The depth 50 cm and width 1.0-1.5 m is sufficient.

Suitability and Limitations:

Its suitability has been judged for following cases:

i. For tree growing in arid and semi-arid areas.

ii. In the areas, with rainfall as low as 150 mm per annum.

iii. In the soils with at least 1.5 m depth, but can also be up to 2 m depth. This is only to ensure adequate root development and storage of harvested water.

iv. Land slope from flat to 5.0%.

v. Topography is not so important, but if there is undulation then block of micro catchments should be sub divided.

Limitations:

The common limitations of this water harvesting technique are as under:

i. These cannot be easily mechanized.

ii. Once, the trees have been planted in the micro catchment, then it is not possible to use machineries for performing tillage operations in the micro catchments.

Method # 2. Contour Bund:

Contour bunds as water harvesting structure, and also for tree planting are simplified form of micro catchments. The construction of bunds can be easily done by using machines; due to this reason this method of water harvesting is found suitable for larger area. These bunds are constructed on contour at close spacing. Also, there is provision of small earth ties, by which the system is divided into individual micro catchment.

In comparison to Negarim micro-catchment, it is more economical, especially for large-scale use on uniform landscape, because of less involvement of earthwork. Also, it has very good compatibility with the cultivation of crops or fodder between the bunds. In addition, like other micro-catchments as water harvesting technique, the runoff yield is high; and when designed correctly then there is no loss of runoff from the system.

The bunding system consists of a series of parallel or about to parallel earthen bunds constructed at the contour. The spacing varies between 5 and 10 m. Bunds are constructed by using the excavated soil from adjacent parallel furrow on upslope side. The infiltration pits are formed at the junction, between lies and bunds. A diversion ditch is also provided to protect the system, if necessary.

The suitabilities of contour bunds are outlined as under:

i. For the areas receiving the annual rainfall from 200-750 mm in semi-arid to arid areas.

ii. The soils with the depth of at least 1.5 m, and preferably up to 2 m are being suitable for this method of water harvesting. In such soils the development of crop/plant root system is very adequate and water storage capacity is also being sufficient.

iii. For the lands with the slopes ranging from flat to 5.0%.

iv. In even topography without gullies or rills.

Limitations:

Few important limitations of this method are mentioned as under:

i. In uneven lands the construction of contour bunds is not suitable.

ii. In erosion susceptible lands also not being suitable, because in such soils if there is overtopping of excess runoff then there is certainly occurrence of soil erosion, and thereby occurrence of damage at low spots.

Size of Micro-Catchment:

The size of unit micro-catchment, i.e. per tree is determined in the same way as the Negarim micro catchments. However, as compared to the others, this system is more flexible, because the size of micro-catchment can be easily altered by adding or subtracting the crossties within the specified bund spacing. In general, the size of micro catchments varies from 10 to 50 sqm for each tree.

Bund and Micro Catchment Specification:

The height of bund varies from 20 to 40 cm depending on the land slope. The shape of bund depends on the type of machine used for construction. It can be done by using the disc plough or motor grader. The bund height should not be less than 20 cm. And base width should be at least 75 cm. Spacing should be 5 or 10 m. The crossties should be at least 2 m long at 2 to 10 m spacing, in which 10 m spacing is recommended for the slope 0.5%, and 5m for steep slopes.

The most common size of micro-catchment for multipurpose trees is 25 m2. For this size of micro-catchment the compatible bund spacing is either 10 m with ties at 2.5 m spacing or 5 m bund spacing with ties at 5 m spacing. Ties are constructed by using the dug soil from infiltration pit. The size of infiltration pit 80 cm x 80 cm x 40 cm is sufficient.

The estimated quantity of earthworks under different spacings of contour bunds are presented in Table 16.10, considering the bund height 25cm and base width 75 cm.

The preparation of layout and construction of contour bunds for runoff harvesting is accomplished under following steps:

Step 1:

Locate the positions of contours by means of line level or a water tube level. The contours are staked at every 50 m. The actual contour is straightened to a gentle curve. The bund’s spacing may be kept slightly wider to accommodate the change in the contour, if any.

Step 2:

Mark the alignment of each bund on the ground, first; and then construction should be started. The bunds should be set at 10m spacing for the slopes up to 0.5%, and at 5m spacing for steeper slopes. After this, construct the bund with the proper care of soil compaction and moisture content in the filled soil.

Step 3:

Determine the catchment size. It is done on the basis of spacing between crossties. For example – if the required size of catchment is 25 m2 and bund’s spacing is to fix at 10 m then the cross-ties should be at 2.5 m apart. Also, construct an infiltration pit in the size of 80 cm x 80 cm x 40 cm in the furrow above the bund. The dug soils should be used for constructing crosstie of 2 m length, 75 cm base width and 25 cm height.

Step 4:

Construct lateral bund of 25 to 30cm height at each side of the block to check the flow of runoff out of the system. For constructing the lateral bunds the soil materials should be excavated from inside the system. Also connect the lateral bunds with the contour bunds.

Step 5:

If there is risk of getting damage of bunding system due to unexpected huge quantity of runoff from up-stream area, then construct a diversion ditch outside the block, so that the runoff could be intercepted, ahead before entering the block.

The dimension of diversion ditch is kept 50 cm as depth and 1 to 1.5m as the width. As precautionary measure, the diversion ditch should be constructed before construction of contour bunds so that the constructed bunds could be under safe mode against turbulent runoff likely to be generated during intense storm.

In bunding system the important matter of maintenance is concerned with the repair of damage parts of flow section, might be due to rodents, soil erosion or due to any other reasons.

After construction of bund, if happens intense storm then there is possibility of getting severe soil erosion from the bund section, because in beginning the soils of bund section are in very loose condition. Sometimes, in worse situation there form several rills in the bund section, which cause breaching of bund. In this condition, the formed rills should be immediately removed by filling the soil materials.

Method # 3. Semi-Circular Bund:

These are the earthen bunds in semi-circular shape. Tips of these bunds are laid at the contour of the area. Overflow is allowed from around the tips of bund. These bunds are of two types, i.e. small structure with close spacing and large structure with wider spacing.

In which, the smaller structures with closer spacing are found suitable for dry areas, with not essentially the uniform topography. These are mainly for rangelands or for fodder production along with water harvesting.

In addition, these are also growing the trees, shrubs, and in few cases for growing crops, also. Based on the location catchment area to the cultivated area, this method may be a short slope or long slope catchment technique. As compared to the other structures such as the trapezoidal bunds, the semi-circular bunds are more efficient to impound water. These bunds cannot be constructed using machineries, is considered as one of the important limitations.

The radius of semi-circular bunds of smaller size is about 6 m; and of bigger size bunds it is about 20 m. These bunds are constructed in staggered form, with runoff producing catchments between them.

The suitability of semi-circular bunds is for following cases:

i. For rangeland improvement.

ii. For fodder production.

iii. For the areas with annual rainfall ranging from 200 to 750 mm, i.e. for arid and semi-arid areas.

iv. Soils, which are not very shallow or saline.

v. Slope less than 2%, but with modified bund design they can be up to 5%.

vi. Uniform topography is suitable for small structure at closer spacing.

Ratio of Catchment Area to Cultivated Area:

In general, the recommended ratio of catchment area to the cultivated area (C:CA) is in lesser range, up to 3:1 for water harvesting systems used for improvement of rangelands and fodder production. The reason of use of low ratio (3:1) is because of requirement of small amount of moisture for appropriate yield. The size of structure is governed by the C: CA. In case of larger ratio, the size of structure is large.

In present case, for design of small size structure the C: CA ratio is considered as 1.4:1 without provision for overflow from the tips. And for larger structures the C: CA ratio is taken as 3:1, with the provision for overflow around the tips, though the occurrence of overflow is normally, rare. However, for larger structure the value of C: CA can be more, but should not be more than 5:1.

1. Small Size Semi-Circular Bund:

i. The radius of small semi-circular bunds is used as 6 m.

ii. The cross section of bund is kept uniform throughout the length 19 m.

iii. The recommended bund height is 25 cm

iv. The side slope is used as 1:1, which results the base width 75 cm for top width of 25 cm.

v. The distance between the tips of adjacent bunds in the same row is 3 m.

vi. The distance between the two rows, from the base of bunds in the first line to the tips of bunds in the second line, is kept 3 m. At this spacing, the total number of bunds per hectare is about 70 to 75.

2. Large Size Semi-Circular Bund:

i. The radius of large size semi-circular bund is kept to the tune of 20 m. However, it can be increased/ decreased depending on the value of selected C: CA ratio. At higher slopes, the radius of curvature is kept small. On the slope 4%, the radius is reduced to 10m.

ii. The cross-section of the bund is changed over its length.

iii. At the wing tip, the height of bund is kept 10 cm, but it can be more towards middle of the base up to 50 cm with side slope 3:1.

iv. The top width is used 10 cm, and corresponding base width 70 cm.

v. Due to larger size of the bund, only 4 structures are adjusted in one hectare area.

vi. The distance between the tips of two adjacent bund in one row is 10 m.

vii. The distance between the base of the upper bund and the tips of the lower one is 30 m. However, it can be increased or decreased according to the selected C: CA ratio and slope range. On the slope 4%, the distance between two adjacent rows should be from 30 to 15 m; and tips of two adjacent structures should be 5 m apart at the place of 10 m. At this specification the total number of bunds per hectare gets increase to 16 for C: CA ratio 3:1.

The quantity of involved earthworks under different layouts of the bunding system is presented in Table 16.11. It should be noted that if diversion ditch is under consideration to construct for disposal of excess runoff from u/s area, then in case of small size semi-circular bunds an extra earthwork at the rate of 62.5 m per 100 m length should be added in the table value of computed earthwork.

The layout and construction procedures for both the types of semi-circular bunds are the same, but their dimensions are different.

The stepwise preparation of layout and construction of semi-circular bunds are outlined as under:

Step 1:

Stake the first contour line at the top of the area with the help of surveying instrument.

Step 2:

Mark the positions of the tips of the semi-circular bunds on the contour. In case of small size bunds the spacing between tips of one structure is kept 12 m, which is normally 2 times of the radius. And in case of larger bunds the tips are spaced at 40 m apart; and the distance to the next bund is 10 m.

Step 3:

Also mark the centre point between the tips of each bund unit. Take a piece of string for the length equal to the radius of bund; and fixed it at the centre point with the help of peg. Hold the string tightly at the other end. And align the semi-circle by swinging the end of the string from one tip to the other; and mark the alignment by pegs or small stones.

Step 4:

Stake the semi-circular bunds in the second and other rows, in the same way. The position of bunds in each row is staggered in relation to the bunds of the other rows. For making this trend, the center points of the bunds in the second row should coincide with the middle of the gaps between the bunds in the first row, and so on. The space between bunds from one row to the next should be according to the selected distance, i.e. 3 m in small size and 30 m in larger size semicircular bunds.

Step 5:

After completing the staking of entire bund position, start the bund construction. It should be done with the excavation of a small trench. The construction of bund should be done in layers of 10-15 cm soil thickness. The soil layering should be followed by proper compaction.

For achieving a good compaction, there should be proper moisture content in the soil. Therefore, it is suggested that if the soil material does not contain proper moisture content, then water should be sprinkled for proper compaction.

Step 6:

After constructing the bunds, place a layer of stones at the bund tips Tor their protection, because the bund tips are very susceptible to get erode due to water flow from one bund to another.

Regarding maintenance, it is very urgent to take care during immediate construction against occurrence of intense storm, because at this stage the bunds are not yet fully consolidated. If proper care is not taken, then there is possibility of severe soil erosion from bund section; and in worse situation the entire bund can get destroyed. Also, if any leakage is there from the bund section then that should also be immediately removed with great care.

Method # 4. Contour Ridges:

These are also called contour furrows or micro-watersheds are mainly used for crop cultivation in addition to water harvesting. In this method the ridges are constructed at the contour of the area in parallel array. Spacing between contour ridges varies from 1 to 2 m. The uncultivated strip of land between the ridges forms micro-catchment for yielding the runoff. The runoff is stored in the furrows towards u/s of the ridges. The crops are grown on both the sides of the furrow.

The construction of contour ridges for water harvesting is very simple. It can be done by hand or by the machines. In construction, the soil is excavated and is placed down slope to form the ridge.

The formed/excavated furrows u/s of the ridges are used for collecting the runoff generated from the micro catchment area. Since, the length of catchment is very short, therefore, the runoff gets generated very efficiently from the micro catchment.

Like other structures, a diversion ditch is also essential to protect the contour ridge system from unexpected huge runoff likely to be generated due to an intense storm event.

The suitability of contour ridges is as under:

i. Contour ridges are suitable to the areas having high rainfall, because low rainfall events are not able to yield the runoff in suitable amount from a very small size catchment, which could be harvested efficiently. Rainfall ranging from 350 to 750 mm is found more suitable.

ii. The soils suitable for agriculture. However, the heavy and compacted soils are unsuitable for construction. The soil slope should be from flat to 5.0%.

iii. Lands with uniform topography are better. The lands with rills or undulations are unsuitable.

Ratio of Catchment Area to Cultivated Area:

In this method, the extent of cultivated area is difficult to demarcate. The crops are planted both the sides of furrow. And runoff is collected in the furrows. Generally, for the spacing of 1.5 m between ridges, the C: CA ratio is taken as 2:1, which refers that for the catchment strip of 1 m the cultivated strip should be 0.5 m. Similarly, for the spacing of 2 m between ridges the C: CA is used as 3:1.

The C: CA ratio can be adjusted by increasing/decreasing the ridge spacing. Practically, 1.5-2.0 m spacing between ridges is recommended for annual crops in semi-arid areas. At this range of ridge spacing the C: CA ratio is 2:1 and 3:1, respectively.

The ridge height must be sufficient to prevent overtopping by the runoff. However, the height from 15 to 20 cm is sufficient. Also, if bund’s spacing is more than 2 m, then ridge height should be increased.

The earth work under construction of contour ridges depends on the ridge spacing, its height and tie. Table 16.12 presents the values of expected earthworks under different ridge spacing, and ridge and tie heights.

It is accomplished under following steps:

Step 1:

Locate the positions of contours by using surveying instruments such as water tube level or line level. For getting a better alignment the contours should be smoothened.

Step 2:

Stake the contour key lines at every 10 or 15 m. After that, the alignment of the ridges is marked between the key lines as per selected spacing. In undulate topography, the contours are likely to fall at closer spacing at one point, while at other points they may be at wider spacing. At the point of convergence, the contour line should be stopped. While in case of divergence few extra lines should be added, in between.

Step 3:

Form the ridges by constructing furrows parallel to the marked alignments with the help of hoe or any suitable plough, and putting the excavated soil down-stream along the furrow.

Step 4:

Construct small crossties at about 5 m intervals. The height of ties should be from 15-20 cm and length 50-75 cm.

Step 5:

Also construct a diversion ditch above the block of contour ridges, if there is risk of getting damage of the formed ridges due to unexpected huge runoff from u/s area. The depth of diversion ditch is kept as 50 cm; width from 1.0 to 1.5 m and longitudinal slope 0.25%. The ditch should be constructed before construction of contour ridges.

It is worth true that, if the contour ridges have been correctly laid and properly constructed, then there is very little possibility of any overtopping or breaching problems. However, a proper inspection should always be there; and if any breaches or any other types of damage is there, then they should be immediately repaired.

Also, the uncultivated area between the ridges should be kept free from vegetations, so that sufficient amount of runoff would be available for flow into the furrows, which is basically need to harvest. Also, at the end of rainy season, the ridges should be reformed to their original dimension.

Method # 5. Trapezoidal Bund:

In this structure, the concept of water harvesting is the same to the semi-circular bund. In this case, three sides of the field are closed by the bunds, while the fourth side is kept open to allow runoff to enter the field. This structure is very simple regarding its design, construction and maintenance.

Trapezoidal bunds are constructed in larger area, i.e. up to 1 ha to harvest large quantity of runoff from the catchments. These bunds have trapezoidal shape.

These are connected with two side bunds or wing walls, which are extended towards upslope at an angle of about 155°. The enclosed area within the bund is used for planting the crops. The size of enclosed area depends on the slope. The area can vary from 0.1 to 1 ha. The trapezoidal bunds can be constructed as single unit, or in clusters.

When several trapezoidal bunds are constructed in cluster, then they are arranged in staggered array. The discharge or overflow takes place around the tips of wing wall. The distance between the tips of adjacent bunds within one row is 20 m; and 30 m spacing between the tips of the lower row and the base of the upper bund.

This harvesting technique is found suitable for the low ground slopes. Although, its construction on slopes more than 1.5% is technically feasible, but involves large quantity of earthwork.

The suitabilities of trapezoidal bunds are outlined as under:

i. They can be used for growing the crops, trees and grass.

For crop production the following requirements are very important:

a. Rainfall ranging from 250 to 500 mm; and area arid to semi-arid.

b. The soils with favorable properties, i.e. significant clay content.

ii. Slopes ranging from 0.25-1.5%, but most suitable slope is less than 0.5%.

iii. Within bund enclosed area the land topography should be uniform.

The dimension or configuration of trapezoidal bund depends on the land slope. Specification is determined by considering the maximum 40 cm depth of water to be stored in the storage area formed by the bund. The recommended dimensions for one unit of trapezoidal bunds are presented in Table 16.13.

Ratio of Catchment Area and Cultivated Area:

The methodology for determining the C: CA ratio and based on the value of C: CA ratio, the number of trapezoidal bunds per hectare can be determined.

The quantity of involved earthwork under bund construction depends on following parameters:

i. Slope of catchment

ii. Length of bund (base)

iii. Length of wing wall

iv. Distance between tips

v. Length of bund (base)

vi. Length of wing wall

vii. Distance between tips

The quantities of earthwork under construction of trapezoidal bunds at different slopes are also presented in Table 16.13.

It is accomplished under following steps:

Step 1:

Establish the land slope using Abney level or line level. And then determine the tips of wing walls. It is carried out from the top of the field. For which, place a peg at the point, which will be the tip of one of the wing walls. The second wing wall tip will be at the same ground level, at the distance, given in Table 16.13. This is located using a line level and a tape, and is marked by the peg.

Step 2:

Stake the points for indicating the dimensions of trapezoidal bund. Four points are considered for this purpose, as shown in Fig. 16.13. In which point-a is established by measuring the distance ‘x’ from point 1 along the line joining points 1 and 2. The point-b is established by measuring the distance V from point 2 along the line joining points 1 and 2.

Points 3 and 4 are the points, of intersection of the base bund and the wing walls, lying at a distance x down slope from points ‘a’ and ‘b’, respectively, measured at right angles to the line joining point 1 and point 2. The right angle can easily be established by using a wooden right angle triangular template. The points 3 and 4 are thereafter pegged.

Step 3:

Check the accuracy of setting. It can be done by measuring the distance between point 3 and 4; 3 and 1, and point 2 and 4.

The measured distance should satisfy the below:

Point 3 – Point 4 = Point a – Point b

Point 1 – Point 3 = Point 2 – Point 4

If there is error more than 0.5 m in any of the three measurements, then procedure for setting should be repeated.

Step 4:

After completing the entire setting in the field, set out the positions with the help of pegs or stones to demarcate the limits of earthwork under construction of trapezoidal bunds. It can be done by marking parallel lines at the given distance from line 3-4. After that demarcate the position of wing bunds.

Step 5:

Start the construction of trapezoidal bunds from the farthest upslope. A care should be taken that before starting the construction work, the soil of the foundation area of the bunds should be loosened so that a good bond with the fill material could be developed there. The construction of bund should be done in two layers. The thickness of each soil layer should be 0.30 m.

The thickness of the first layer should be gradually tapered, off to zero, as filling precedes upslope along the wing bunds. Similarly, the thickness of second layer should also be tapered to 0.20 m at the tips. As precautionary measure, after filling the soil in layers they should be thoroughly compacted by rolling, ramming or stamping; and also watered before compaction, if soil does not contain proper moisture content.

Step 6:

Since, the water flow takes place from around the tips of the bund; therefore, these points are very much susceptible to get erode due to water flow. Considering this point in view, prevent the soil erosion from the tips, by shaping with a small extension to lead the water away, safely. Also, the extended portion should be pitched with the help of stones.

Step 7:

If the size of catchment area is very large in relation to the bunded area, then construct a diversion ditch for preventing the excessive inflow to the bunds. The depth of diversion ditch is kept about 50 cm; width from 1.0 to 1.5 m and longitudinal bed slope 0.25%.

The excavated soil from ditch construction should be used for constructing the embankment on the down slope side, which also facilitates in diverting the runoff from the bunds. If the catchment is not of adequate size, then interception ditches can also be constructed to lead the runoff from adjacent catchment to the bunds.

The bund sections are likely to get damage mainly due to breaching, which is because of following reasons:

i. Soil erosion

ii. Burrowing due to rodents, and

iii. Animal movement

In the beginning, when bund is newly constructed, there is possibility of severe soil erosion due to rainfall. In worse situation, a network of rills gets develop at bund face; and if they are not properly removed from there, then they join together, and thus breach the bund. Sometimes, bund’s breaching also gets happen, when soil compaction is not properly done during bund construction.

The burrowing animals like rodents make the holes in the bund body. Several such holes join together, and make the section very weak; as result the bund gets breach due to settlement.

The animals normally graze the vegetations grown on the bund body, in usual way without any restriction. In this situation, the soil of bund section gets disturbed, which also cause breaching.

In addition to the above points of maintenance of bund, the wing tips are frequently under water action; therefore, they should be properly inspected; and if any repair is there, they must be repaired, immediately.

Method # 6. Contour Stone Bund:

The principle of water harvesting by the contour stone bunds is to slow down and filter the runoff, and thereby increasing the infiltration rate. The water conserved in the soil profile, and trapped sediments lead directly to improve the field condition for crop cultivation. This technique is more suitable where stones are readily available in nearby area. These bunds are constructed at the contour of the area.

The spacing of stone bunds varies between 15 and 30 m depending on the amount of stones and labours availability, mainly. The required amount of stones and labours per hectare are presented in Table 16.14. There is no need for diversion ditches or provision of spillways.

If bund construction is done along the contour of the area, then system becomes very effective to harvest the rainwater and for crop production as well. Since, in this structure there is no spillway for allowing the water to the storage area; therefore, the possibility of getting damage due to concentrated water flow is not there.

Also, the stone pieces used for bund construction act as semi permeable barrier (filtering media) along entire length, which in turn to spread the runoff in better way, as compared to the other structures. In addition, the stone bunds require very less maintenance.

The suitabilities of contour stone bunds for crop production are outlined as under:

i. Rainfall ranging from 200 to 750 mm, i.e. for arid & semi-arid areas.

ii. Agricultural lands.

iii. Slope preferably less than 2%.

iv. Even or uneven land topography.

v. In the area where stones are readily available.

The specifications of contour stone bunds are mentioned as under:

i. Initial minimum bund height is 25 cm.

ii. Base width of bund is from 35-40 cm.

iii. The bund should be constructed with a shallow foundation of 5-10 cm depth to prevent undermining by runoff.

iv. Bund spacing is 20 m for the slope less than 1%; and 15 m for the slope 1-2%.

v. The bund should be constructed according to the “reverse filter” principle, i.e. smaller stones at u/s of the bigger stones to create rapid siltation of suspended materials.

Step 1:

Determine the average slope of the field to decide spacing of the bunds. After that set-out the contour line and pegged, individually. The horizontal spacing of about 20 m is recommended for the slopes less than 1%, and 15 m for 1-2% slopes.

Step 2:

After locating the positions of contour lines in the field, smooth the contour lines by moving individual pegs up/down slope. For the ground slope up to 1.0 %, the pegs can be moved 2 m upslope/down slope to develop a smooth curve.

Step 3:

For placing the stone pieces to construct contour stone bund, dig a shallow trench or foundation along the smoothened contour line. The trench can be made by hand tools or plough. The depth of trench is about 5-10 cm and base width 35-40 cm.

Step 4:

Start the construction of bund by placing the large size stones at the base of the trench and towards down slope side of the trench. Thereafter, place the smaller stones at front (u/s) and on the top of it. Also plug the gap formed between bigger stones with the help of small stones. If gravelly stones are there at the site, then also laid a line of fine filter along the up slope face of bund, using the gravelly stones.

The maintenance of contour stone bunds is done under following aspects:

i. It is common phenomena that due to heavy runoff flow, the stones are dislodged from their place. This results into damage of the structure. If such type of happening is there, then that should be immediately removed.

ii. If there has been formed gaps in the stone bund, then they should be immediately filled by using small stones. If it is not done, then there is possibility of development of tunnel through bund section.

iii. These bunds are likely to get silted up at their u/s side, as result the water harvesting storage capacity gets reduce. This type of happening normally takes place after 3 seasons or more; and is more predominant where bunds are constructed at greater spacing on steep slopes. To avoid such type of problem the stones should be properly packed, so that the runoff may get flow easily from the gaps between stone packing.

iv. The grasses should also be planted along the bund length. The root system binds the stones together, as result the stones remain at their place for longer time period.

Method # 7. Permeable Rock Dams:

Permeable rock dams are also one of the water harvesting structures, constructed at the valley bottom. These are used for floodwater harvesting, in which runoff water is spread. The water gets stored in the permeable zone of dam. The valley bottom consists of deposited sediment layer, which is very permeable in nature. This is called permeable zone of dam. In addition to use for water harvesting, these dams are also used for gully healing.

These are constructed in valley width with less in height across the valley using rocks (occasionally gabion baskets can also be used). The central part of dam is being perpendicular to the watercourse. Dam is extended into either sides of the valley. The runoff gets spread in the valley across the dam, which percolates into the deposited soil strata. After few months the dam gets silted up with fertile deposits.

The stored water in the dam is utilized for crop cultivation. The permeable rock dams are site-specific, require considerable amount of loose stones as well as the transport facility. Dimension of dam is shown in Fig. 16.17.

The suitability of this structure for water harvesting along with crop cultivation can be under following conditions:

i. Rainfall ranging from 200 to 750 mm, i.e. for arid and semi-arid areas.

ii. All agricultural lands.

iii. Slopes below 2% for effective water spreading.

iv. Wide and shallow valley beds.

Its various specifications are mentioned as under:

i. The height of dam varies from 50 to 70 cm.

ii. The height at central portion of the dam including the spillway (if required) may be up to maximum 2 m above the gully bed.

iii. The dam wall or ‘spreader’ can be up to 1000 m across the widest valley beds.

iv. The length varies from 50 to 300 m.

v. The amount of stones required for constructing large structures can be up to 2000 tons. However, table 16.15 provides the quantity of stones required per hectare basis for construction of typical permeable rock dams under different land slopes and spacings.

vi. The side slopes are used as 3:1 or 2:1 (horizontal: vertical) at the downstream side; and 1:1 or 1:2 on the upstream side. Flatter side slope makes the structure more stable, but more expensive.

vii. The dam foundation should be constructed by excavating the trench of about 10 cm depth. In erodible soils, a layer of gravel or at least smaller stones, should be placed in the foundation trench.

Layout and Construction:

Step 1:

Select the site for its construction, which is done by consulting the beneficiaries and the technicians. After identifying the suitable site, determine the provision for spillway in the permeable dam. For this purpose a thumb rule is followed, which states that if the valley or gully is less than one hi deep, then there is no need of spillway.

In site selection, it is also taken as an important point that the permeable rock dam should not be constructed immediately above the gully head, as there is the risk of fall of dam into the gully when there is severe and continuous erosion at the gully head.

Step 2:

If it is sought to provide spillway in the dam, then first construct the spillway at suitable point. The construction of spillway can be done by using the gabions, because loose stones are easily destabilized by heavy floods.

The construction of gabion spillway should be done as per below:

i. Dig a trench for foundation of dam. In foundation construction the small stones should be placed at the bottom.

ii. In spillway there should be an apron of large rocks to break the erosive force of overflow.

iii. The d/s of spillway should be protected by stone pitching to prevent enlargement of the gully.

Step 3:

Indicate the alignment of main dam walls, starting from the centre of the valley. As precautionary measure the alignment should be on the contour, or close to the contour.

Step 4:

Fix the specification of dam section. As per recommendation the base width of dam should be 280 cm; height 70 cm and side slope 1:1 towards upstream and 3:1 at downstream. However, the size of dam may be changed depending on the size of runoff contributing catchment area.

Step 5:

Preferably use the large size stones for casing of the wall. For this purpose the stones of 30 cm diameter or more are found suitable. The construction should be accomplished in layers of suitable thickness of stones. Erection of dam for its complete height in different layers enables the dam to withstand against floods, strongly.

As precautionary measures, the soil materials should not get mixed with the stones, because they destabilize the structure. The small stones should be packed inside the dam section. The u/s and d/s slopes should be in proper range. Also, the dam wall should be level throughout length.

Step 6:

If a number of permeable rock dams are required to construct in series, then they should be constructed with the provision of designed vertical interval. The provision of VI should be given from the top of the valley and proceeded down. The VI should be equal to the height of the dam, so that the bottom of dam at upper side would be in the level of top of lower side dam. However, the VI can also be computed by suing the following formula –

In which, HI is the horizontal interval (m); VI is the vertical interval (m) and % slope is the land gradient expressed in percent. For example, if HI is 70 m and land gradient is 1%, then VI will be equal to 0.70m.

If the design of dam has been done correctly; and construction has also been done as per design dimension, then there is no need of attentive care and maintenance. However, sometimes when an extreme rainfall event takes place, then runoff generated from the contributing catchment is being very high, which likely to overtop the dam.

In this condition, the stones are washed away from their packing place. In worse situation, there is also the possibility of development of tunnels through the dam section or from below the foundation. If such type of problems has been developed, then they must be immediately removed by using small size stones.

Method # 8. Water Spreading Bunds:

The water spreading bunds are normally used in the condition when trapezoidal bunds are not being suitable for the site, for water harvesting. This technique is site specific. Normally, these are more suitable where runoff rate is very high; and there is possibility of getting damage of trapezoidal bunds due to high runoff rate. Also, where the crops grown are very susceptible to temporary water ponding, the water spreading type bunds are very suitable.

By this bund a huge area is isolated, in which flood water is allowed to spread, but not allowed to get pond in the area. The spread water ultimately gets infiltrate into the soil profile and enriches the soil moisture content. Such bunds are mainly used to spread the floodwater, which has either been diverted from any watercourse or has been naturally spilled onto the floodplain. These bunds are also suitably used for flood control.

The suitabilities of water spreading type bunds are as below:

i. Rainfall ranging from 100 to 350 mm; normally in hyper-arid/arid areas only.

ii. The alluvial tracts or floodplains with deep fertile soils.

iii. Suitable for the slopes 1% or less.

iv. Flat topography.

v. The area close to the river or watercourse.

vi. This technique is suitable for arid areas where floodwater is the only source for crop or fodder production.

The specifications of water spreading bunds are outlined as under for following cases of land slope:

Case (1):

Slope Less than 0.5%:

i. Straight bunds are used for water spreading. In these bunds both the ends are kept open for allowing the floodwater.

ii. The bunds are spaced at 50 m interval.

iii. Bunds are overlapped, so that the overflow from one bund should be intercepted by the bund lying just below.

iv. The bund height 60 cm; base width 4.1 m, and top width as 50 cm.

v. The side slopes 3:1.

vi. Maximum bund length is kept 100 m.

Case (2):

Slope 0.5 to 1.0%:

i. Graded bunds are constructed for water spreading.

ii. Bund’s cross-section is uniform with the grade of 0.25%.

iii. A short wing wall is also provided to the upper end of each bund for interception of the flow around the bund, above.

iv. The spacing between bunds depends on the land slope.

v. The bund cross section is the same to the contour bunds on lower slopes.

vi. The maximum length of base bund is about 100 m.

The quantity of earthwork under construction of water spreading bunds at different slopes and types of bunds are presented in table 16.16 assuming the bund cross section 1.38 sqm.

Layout and Construction:

Step 1:

Determine the land slope to select an appropriate bunding system.

Step 2:

If the land slope is less than 0.5%, then construct straight bunds at 50 m interval. The bunds should be arranged in staggered form. If the land slope is more than 0.5% and up to 1.0% then construct graded bunds. The grade along bund should be provided to the tune of 0.25% for the ground slope 0.5%.

Step 3:

Mark the limits of fill in the dam section using stakes or stones at the distance of 2.05 m on either sides of the centerline.

Step 4:

Start construction from the top of the field. The soil should be excavated from both the sides to form the bunds. And in the trench the earth ties should also be foreseen at closer spacing to prevent scouring. The construction of bund is carried out in 2 layers of 30 cm fill thickness, each. Compaction of fill soil should also be done, simultaneously.

Step 5:

Do stone pitching at the ends of contour bunds, and also at the tip of wing walls to check the damage likely to be occurred due to flow around the bunds.

Maintenance:

Maintenance of water spreading dam is performed under following respects:

i. This structure is also likely to get affected by the same causes, as normally found in the other water harvesting structures, such as breaching etc. Therefore, a preventive measure should be adopted to fight against them.

ii. For getting information about any kind of defects have been developed in the dam section, a regular inspection is very essential. It should be done, properly.

iii. After completing the dam construction, the vegetation of suitable species should be planted in the dam section, so that the dam could be covered with the grass cover. This keeps the stones, together, as result their removal due to water flow gets check.