ADVERTISEMENTS:

Here is an essay on the applications of solar energy technology.

Applications of Solar Energy Technology

Essay Contents:

- Essay on Architecture and Urban Planning

- Essay on Agriculture and Horticulture

- Essay on Solar Lighting

- Essay on Solar Water Heating

- Essay on Solar-Powered Pump

- Essay on Solar Furnaces

- Essay on Heating, Cooling and Ventilation

- Essay on Water Treatment Using Solar Energy

- Essay on Solar Cooker

- Essay on Process Heat Using Solar Energy

- Essay on Solar Chemical

- Essay on Solar Vehicles

1. Essay on Architecture and Urban Planning:

ADVERTISEMENTS:

Sunlight has influenced building design since the beginning of architectural history. Advanced solar architecture and urban planning methods were first employed by the Greeks and Chinese, who oriented their buildings toward the south to provide light and warmth.

The common features of passive solar architecture are orientation relative to the Sun, compact proportion (a low surface area to volume ratio), selective shading (overhangs) and thermal mass. When these features are tailored to the local climate and environment they can produce well-lit spaces that stay in a comfortable temperature range.

The most recent approaches to solar design use computer modeling tying together solar lighting, heating and ventilation systems in an integrated solar design package. Active solar equipment such as pumps, fans and switchable windows can complement passive design and improve system performance.

Urban heat islands (UHI) are metropolitan areas with higher temperatures than that of the surrounding environment. The higher temperatures are a result of increased absorption of the solar light by urban materials such as asphalt and concrete, which have lower albedos and higher heat capacities than those in the natural environment. A straightforward method of counteracting the UHI effect is to paint buildings and roads white and plant trees.

2. Essay on Agriculture and Horticulture:

Agriculture and horticulture seek to optimize the capture of solar energy in order to optimize the productivity of plants. Techniques such as timed planting cycles, tailored row orientation, staggered heights between rows and the mixing of plant varieties can improve crop yields.

While sunlight is generally considered a plentiful resource, the exceptions highlight the importance of solar energy to agriculture. During the short growing seasons of the Little Ice Age. French and English farmers employed fruit walls to maximize the collection of solar energy. These walls acted as thermal masses and accelerated ripening by keeping plants warm.

Early fruit walls were built perpendicular to the ground and facing south, but over time, sloping walls were developed to make better use of sunlight. In 1699, Nicolas Fatio de Duillier even suggested using a tracking mechanism which could pivot to follow the Sun.

ADVERTISEMENTS:

Applications of solar energy in agriculture aside from growing crops include pumping water, drying crops, brooding chicks and drying chicken manure. More recently the technology has been embraced by vinters, who use the energy generated by solar panels to power grape presses.

Greenhouses convert solar light to heat, enabling year-round production and the growth (in enclosed environments) of speciality crops and other plants not naturally suited to the local climate. Primitive greenhouses were first used during Roman times to produce cucumbers year-round.

The first modern greenhouses were built in Europe in the 16th century to keep exotic plants brought back from explorations abroad. Greenhouses remain an important part of horticulture today and plastic transparent materials have also been used to similar effect in polytunnels and row covers.

3. Essay on Solar Lighting:

The history of lighting is dominated by the use of natural light. The Romans recognized a right to light as early as the 6th century. In the 20th century artificial lighting became the main source of interior illumination but day-lighting techniques and hybrid solar lighting solutions are ways to reduce energy consumption.

Day lighting systems collect and distribute sunlight to provide interior illumination. This passive technology directly offsets energy use by replacing artificial lighting and indirectly offsets non-solar energy use by reducing the need for air-conditioning. Although difficult to quantify, the use of natural lighting also offers physiological and psychological benefits compared to artificial lighting.

Day lighting design implies careful selection of window types, sizes and orientation; exterior shading devices may be considered as well. Individual features include saw tooth roofs, clerestory windows, light shelves, skylights and light tubes.

They may be incorporated into existing structures, but are most effective when integrated into a solar design package that accounts for factors such as glare, heat flux and time-of-use. When day lighting features are properly implemented they can reduce lighting-related energy requirements by 25%.

ADVERTISEMENTS:

Hybrid solar lighting is an active solar method of providing interior illumination. HSL systems collect sunlight using focusing mirrors that track the Sun and use optical fibers to transmit it inside the building to supplement conventional lighting.

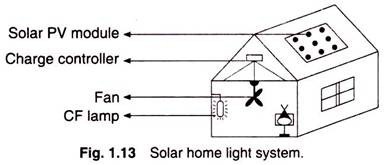

Solar Home Light System:

Home lighting system are powered by solar energy using solar cells that convert solar energy (sunlight) directly to electricity. The electricity is stored in batteries and used for the purpose of lighting whenever required.

These systems are useful in non-electrified rural areas and as reliable emergency lighting system for important domestic, commercial and industrial applications. The SPV systems have found important application in the dairy industry for lighting milk collection/chilling centers mostly located in rural areas.

The solar home lighting system is a fixed installation designed for domestic application. The system comprises of solar PV module (solar cells), charge controller, battery and lighting system (lamps and fans). The schematic of the HLS is given below.

The solar module is installed in the open on roof/terrace – exposed to sunlight and the charge controller and battery are kept inside a protected place in the house. The solar module requires periodic dusting for effective performance.

The systems are designed, to give a daily working time of 3-4 hours with a fully charged battery. The system provides for buffer storage for 1-2 non-sunny/cloudy days.

The technical detail of some of the systems is given as below:

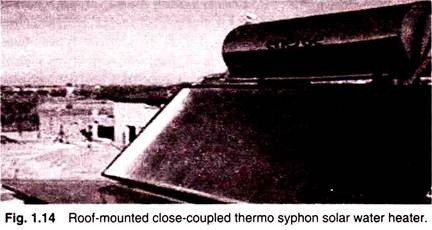

4. Essay on Solar Water Heating:

Solar water heating (SWH) systems are a mature renewable energy technology which have been accepted in most countries for many years. SWH has been widely used in Israel, Australia, Japan, Austria and China.

In a ‘close-coupled’ SWH system the storage tank is horizontally mounted immediately above the solar collectors on the roof. No pumping is required as the hot water naturally rises into the tank through thermo siphon flow. In a ‘pump-circulated’ system the storage tank is ground or floor mounted and is below the level of the collectors; a circulating pump moves water or heat transfer fluid between the tank and the collectors.

SWH systems are designed to deliver the optimum amount of hot water for most of the year. However, in winter there sometimes may not be sufficient solar heat gain to deliver sufficient hot water. In this case a gas or electric booster is normally used to heat the water.

Solar Water Heater Technology:

In order to heat water using solar energy, a collector, often fastened to a roof or a wall facing the sun, heats working fluid that is either pumped (active system) or driven by natural convection (passive system) through it.

The collector could be made of a simple glass topped insulated box with a flat solar absorber made of sheet metal attached to copper pipes and painted black, or a set of metal tubes surrounded by an evacuated (near vacuum) glass cylinder. In industrial cases a parabolic mirror can concentrate sunlight on the tube.

Heat is stored in a hot water storage tank. The volume of this tank needs to be larger with solar heating systems in order to allow for bad weather, and because the optimum final temperature for the solar collector is lower than a typical immersion or combustion heater.

The heat transfer fluid (HTF) for the absorber may be the hot water from the tank, but more commonly (at least in active systems) is a separate loop of fluid containing anti-freeze and a corrosion inhibitor which delivers heat to the tank’ through a heat exchanger (commonly a coil of copper tubing within the tank).

Another lower-maintenance concept is the ‘drain-back’- no anti-freeze is required; instead all the piping is sloped to cause water to drain back to the tank. The tank is not pressurized and is open to atmospheric pressure. As soon as the pump shuts off, flow reverses and the pipes are empty before freezing could occur.

Residential solar thermal installations fall into two groups- passive (sometimes called ‘compact’) and active (sometimes called ‘pumped’) systems. Both typically include an auxiliary energy source (electric heating element or connection to a gas or fuel oil central heating system) that is activated when the water in the tank falls below a minimum temperature setting such as 55°C.

Hence, hot water is always available. The combination of solar water heating and using the back-up heat from a wood stove chimney to heat water can enable a hot water system to work all year round in cooler climates, without the supplemental heat requirement of a solar water heating system being met with fossil fuels or electricity.

When a solar water heating and hot-water central heating system are used in conjunction, solar heat will either be concentrated in a pre-heating tank that feeds into the tank heated by the central heating, or the solar heat exchanger will replace the lower heating element and the upper element will remain in place to provide for any heating that solar cannot provide. However, the primary need for central heating is at night and in winter when solar gain is lower.

Therefore, solar water heating for washing and bathing is often a better application than central heating because supply and demand are better matched. In many climates, a solar hot water system can provide up to 85% of domestic hot water energy.

This can include domestic non-electric concentrating solar thermal systems. In many northern European countries, combined hot water and space heating systems are used to provide 15 to 25% of home heating energy.

Types of Solar Water Heating (SWH) Systems:

The type and complexity of a solar water heating system is mostly determined by:

i. The changes in ambient temperature during the day-night cycle.

ii. Changes in ambient temperature and solar radiation between summer and winter.

iii. The temperature of the water required from the system.

The minimum efficiency of the system is determined by the amount or temperature of hot water required during winter (when the largest amount of hot water is often required). The maximum efficiency of the system is determined by the need to prevent the water in the system from becoming too hot (to boil, in an extreme case). There are two main categories of solar water heating systems. Passive systems rely on convection or heat pipes to circulate water or heating fluid in the system, while active systems use a pump.

In addition, there are a number of other system characteristics that distinguish different designs:

i. The type of collector used.

ii. The location of the collector – roof mount, ground mount, wall mount.

iii. The location of the storage tank in relation to the collector.

iv. The method of heat transfer – open-loop or closed-loop (via heat exchanger).

v. Photovoltaic thermal hybrid solar collectors can be designed to produce both hot water and electricity.

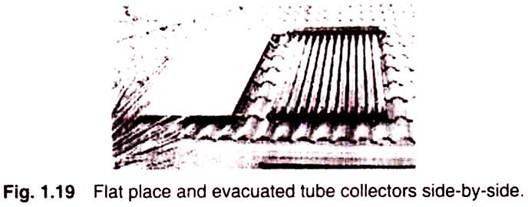

The most common types of solar water heaters are evacuated tube collectors (44%) and glazed flat plate collectors (34%) generally used for domesting hot water, and unglazed plastic collectors (21%) used mainly to heat swimming pools.

Collectors Used in Modern Domestic Solar Water Heating Systems:

Solar thermal collector capture and retain heat from the sun and transfer this heat to a liquid.

Two important physical principles govern the technology of solar thermal collectors:

i. Any hot object ultimately returns to thermal equilibrium with its environment, due to heat loss from the hot object. The processes that result in this heat loss are conduction, convection and radiation. The efficiency of a solar thermal collector is directly related to heat losses from the collector surface (efficiency being defined as the proportion of heat energy that can be retained for a predefined period of time).

Within the context of a solar collector, convection and radiation are the most important sources of heat loss. Thermal insulation is used to slow down heat loss from a hot object to its environment. This is actually a direct manifestation of the second law of thermodynamics but we may term this the ‘equilibrium effect’.

ii. Heat is lost more rapidly if the temperature difference between a hot object and its environment is larger. Heat loss is predominantly governed by the thermal gradient between the temperature of the collector surface and the ambient temperature. Conduction, convection as well as radiation occur more rapidly over large thermal gradients. We may term this the ‘delta-t effect’.

The most simple approach to solar heating of water is to simply mount a metal tank filled with water in a sunny place. The heat from the sun would then heat the metal tank and the water inside. Indeed, this was how the very first SWH systems worked more than a century ago.

However this setup would be inefficient due to an oversight of the equilibrium effect, above once when the tank and water has started to be heated, the heat gained would be lost back into the environment, ultimately until the water in the tank would assume the ambient temperature. The challenge is therefore to limit the heat loss from the tank, thus delaying the time until thermal equilibrium is reached.

ICS or batch collectors overcome the above problem by putting the water tank in a box that limits the loss of heat from the tank back into the environment. This is achieved by encasing the water tank in a glass-topped box that allows heat from the sun to reach the water tank. However, the other walls of the box are thermally insulated, reducing convection as well as radiation to the environment.

In addition, the box can also have a reflective surface on the inside. This reflects heat lost from the tank back towards the tank. In a simple way one could consider an ICS solar water heater as a water tank that has been enclosed in a type of ‘oven’ that retains heat from the sun as well as heat of the water in the tank. Using a box does not eliminate heat loss from the tank to the environment, but it largely reduces this loss.

There are many variations on this basic design, with some ICS collectors comprising several smaller water containers and even including evacuated glass tube technology. This is because ICS collectors have a characteristic that strongly limits the efficiency of the collector- a small surface-to-volume ratio.

Since the amount of heat that a tank can absorb from the sun is largely dependent on the surface of the tank directly exposed to the sun, it follows that a small surface would limit the degree to which the water can be heated by the sun. Cylindrical objects such as the tank in an ICS collector inherently have a small surface-to-volume ratio and most modern collectors attempt to increase this ratio for efficient warming of the water in the tank.

Flat plate collectors are an extension of the basic idea to place a collector in an ‘oven’-like box. Here, a pipe is connected to the water tank and the water is circulated through this pipe and back into the tank. The water tank is now outside the collector that only contains the pipes. Since the surface-to-volume ratio increases sharply as the diameter of a pipe decreases, most flat-plate collectors have pipes less than 1 cm in diameter.

The efficiency of the heating process is therefore sharply increased. The design of a flat-plate collector therefore typically takes the shape of a flat box with a robust glass top oriented towards the sun, enclosing a network of piping. In many flat-plate collectors the metal surface of the pipe is increased with flat metal flanges or even a large, flat metal plate to which the pipes are connected.

Since the water in a flat-plate collector usually reaches temperatures much higher than that of an ICS, the problem of radiation of heat back to the environment is very important, even though a box-like ‘oven’ is used. This is because the ‘delta-t- effect’ is becoming important.

Formed collectors are a degenerate modification of a flat-plate collector in that the piping of the collector is not enclosed in a box-like ‘oven’. Consequently these types of collectors are much less efficient for domestic water heating. However, since water colder than the ambient temperature is heated, these collectors are efficient for that specific purpose.

Evacuated tube collectors are a way in which heat loss to the environment, inherent in flat plates, has been reduced. Since heat loss due to convection cannot cross a vacuum, it forms an efficient isolation mechanism to keep heat inside the collector pipes. Since two flat sheets of glass are normally not strong enough to withstand a vacuum, the vacuum is rather created between two concentric tubes.

Typically, the water piping in an evacuated tube collector is therefore surrounded by two concentric tubes of glass with a vacuum in between that admits heat from the sun (to heat the pipe) but which limits heat loss back to the environment. The inner tube is coated with a thermal absorbent.

Flat plate collectors are generally more efficient than evacuated tube collectors in full sunshine conditions. However, the energy output of flat plate collectors drops off rapidly in cloudy or cool conditions compared to the output of evacuated tube collectors that decrease less rapidly.

Economics Related to Solar Water Heating:

i. Energy Cost:

The amount of heat delivered by a solar water heating system depends primarily on the amount of heat delivered by the sun at a particular place (the insolation). In tropical places the insolation can be relatively high, e.g., 7 kW.h per day, whereas the insolation can be much lower in temperate areas where the days are shorter in winter, e.g., 3.2 kW.h per day. Even at the same latitude the average insolation can vary a great deal from location to location due to differences in local weather patterns and the amount of overcast.

With most solar water heating systems, the energy output scales linearly with the surface area of the absorbers. Therefore, when comparing figures, take into account the absorber area of the collector because collectors with less absorber area yield less heat, even within the 2 m2 range.

ii. System Cost:

In sunny, warm locations, where freeze protection is not necessary, an ICS (batch type) solar water heater can be extremely cost effective. In higher latitudes, there are often additional design requirements for cold weather, which add to system complexity. This has the effect of increasing the initial cost (but not the life-cycle cost) of a solar water heating system to a level much higher than a comparable hot water heater of the conventional type.

The biggest single consideration is therefore the large initial financial outlay of solar water heating systems. Offsetting this expense can take several years and the payback period is longer in temperate environments where the insolation is less intense.

When calculating the total cost to own and operate, a proper analysis will consider that solar energy is free, thus greatly reducing the operating costs, whereas other energy sources, such as gas and electricity, can be quite expensive over time.

Thus, when the initial costs of a solar system are properly financed and compared with energy costs, then in many cases the total monthly cost of solar heat can be less than other more conventional types of hot water heaters (also in conjunction with an existing hot water heater). At higher latitudes, solar heaters may be less effective due to lower solar energy, possibly requiring larger and/or dual-heating systems. In addition, federal and local incentives can be significant.

The calculation of long term cost and payback period for a household SWH system depends on a number of factors.

Some of these are:

i. Price of purchasing solar water heater (more complex systems are more expensive),

ii. Efficiently of SWH system purchased,

iii. Installation cost,

iv. State or government subsidy for installation of a solar water heater,

v. Price of electricity per kW.h,

vi. Number of kW.h of electricity used per month by a household,

vii. Annual tax rebates or subsidy for using renewable energy,

viii. Annual maintenance cost of SWH system, and

ix. Savings in annual maintenance of conventional (electric/gas/oil) water heating system.

Considerations during the installation of a solar water heating (SWH) system:

i. Except in rare instances it will be inefficient to install a SWH system with no electrical or gas or other fuel backup. Many SWH systems (e.g., thermosiphon systems) have an integrated electrical heater in the integrated tank. Conversely, many active solar systems incorporate a conventional ‘geyser’. But even in a tropical environment there are rainy and cloudy days when the insolation is low and the temperature of the water in the tank increases very little on account of solar heating. Electrical or other backup ensures a reliable supply of hot water.

ii. The installation of a SWH system needs to be complemented with efficient insulation of all the water pipes connecting the collector and the water storage tank, as well as the storage tank (or ‘geyser’) and the most important warm water outlets.

The installation of efficient lagging significantly reduces the heat loss from the hot water system. The installation of lagging on at least two meters of pipe on the cold water inlet of the storage tank reduces heat loss, as does the installation of a ‘geyser blanket’ around the storage tank (if inside a roof). In cold climates the installation of lagging and insulation is often performed even in the absence of a SWH system.

iii. If a photovoltaic (PV) panel is used to drive the pump in an active system, the installation of a controller is crucial. This prevents the pump from switching on early in the morning when there is light to drive the pump but while the collector is still cold. This causes the hot water in the storage tank to be cooled. Some modern pumps can operate even in fairly low light levels, causing unwanted circulation through the collector.

iv. Usually a large SWH system is more efficient economically than a small system. This is because the price of a system is not linearly proportional to the size of the collector, so a square meter of collector is cheaper in a larger system. If this is the case, it pays to use a system that covers all or nearly all of the domestic hot water needs, and not only a small fraction of the needs. This facilitates more rapid cost recovery.

v. Due to the modularity of an evacuated tube collector panel, this technology allows the adjustment of the collector size by removing some tubes or their heat pipes. Budgeting for a larger than required array of tubes therefore allows for the customization of collector size to the needs of a particular application, especially in warmer climates.

5. Essay on Solar-Powered Pump:

A solar powered pump is a pump running on the power of the sun. A solar powered pump can be more environmentally friendly and economical in its operation.

A solar powered pump consists of 3 parts:

i. The actual water pump.

ii. The engine.

iii. The energy source being powered by the sun.

The solar water pumping system is a stand-alone system operating on power generated using solar PV (photovoltaic) system. The power generated by solar cells is used for operating DC surface centrifugal mono-block pump set for lifting water from bore/open well or water reservoir for minor irrigation and drinking water purpose.

The system schematic is shown in the figure below. The system requires a shadow-free area for installation of the Solar Panel. The system is provided with 1800 W solar PV panel (24 nos. X 75 Wp) and 2 HP centrifugal DC mono-block/AC submersible with inverter.

The average water delivery of 2 HP solar pump will be around 1.38 to 1.40 lakh litre per day, for a suction head of 6 metres and dynamic head of 10 metres. The size of suction & delivery lines is 2.5 inches (62.5 mm).

Advantages of solar pump sets:

i. No fuel cost-uses abundantly available free sun light.

ii. No conventional grid electricity required.

iii. Long operating life.

iv. Highly reliable and durable- free performance.

v. Easy to operate and maintain.

vi. Eco-friendly.

vii. Saving of conventional diesel fuel.

Solar PV water pumping systems are used for irrigation and drinking water in India. The majority of the pumps are fitted with a 200 watt – 3,000 watt motor are powered with 1,800 Wp PV array which can deliver about 140,000 liters of water/day from a total head of 10 meters.

6. Essay on Solar Furnaces:

A solar furnace is a structure used to harness the rays of the sun in order to produce high temperatures. This is achieved by using a curved mirror (or an array of mirrors) acting as a parabolic reflector to concentrate light (Insolation) on to a focal point. The temperature at the focal point may reach up to 3,000 degrees Celsius, and this heat can be used to generate electricity, melt steel or make hydrogen fuel.

This device is extremely dangerous. It should not be constructed or operated by anyone who does not observe proper safety precautions. It will instantly destroy flesh. It will melt metals, ceramics, and most any other material. Once should wear proper protective equipment when operating this device.

The largest solar furnace in the world is at Odeillo in the Pyrenees-Orientales in France, opened in 1970. It employs an array of plane mirrors to gather the rays of light from the sun, reflecting them on to a larger curved mirror.

The rays are then focused onto an area the size of a cooking pot and can reach 3,500°C (6,330°F), depending on the process installed, for example:

i. About 1,000°C (1,830°F) for metallic receivers producing hot air for the next generation solar towers.

ii. About 1,400°C (2,550°F) to produce hydrogen by cracking methane molecules.

iii. Up to 2,500°C (4,530°F) to test materials for extreme environment such as nuclear reactors or space vehicle atmosphere reentry.

iv. up to 3,500°C (6,330°F) to produce nanomaterial’s by solar induced sublimation and controlled cooling, such as carbon nanotube or zinc nanoparticles.

7. Essay on Heating, Cooling and Ventilation:

(HVAC) systems account for approximately 30% (4.65 EJ) of the energy used in commercial buildings and nearly 50% (10.1 EJ) of the energy used in residential buildings in developed countries. Solar heating, cooling and ventilation technologies can be used to offset a portion of this energy.

Thermal mass is any material that can be used to store heat—heat from the Sun in the case of solar energy. Common thermal mass materials include stone, cement and water. Historically they have been used in arid climates or warm temperate regions to keep buildings cool by absorbing solar energy during the day and radiating stored heat to the cooler atmosphere at night.

However they can be used in cold temperate areas to maintain warmth as well. The size and placement of thermal mass depend on several factors such as climate, day lighting and shading conditions. When properly incorporated, thermal mass maintains space temperatures in a comfortable range and reduces the need for auxiliary heating and cooling equipment.

A solar chimney (or thermal chimney, in this context) is a passive solar ventilation system composed of a vertical shaft connecting the interior and exterior of a building. As the chimney warms, the air inside is heated causing an updraft that pulls air through the building. Performance can be improved by using glazing and thermal mass materials in a way that mimics greenhouses.

8. Essay on Water Treatment using Solar Energy:

Solar distillation can be used to make saline or brackish water potable. The other process includes solar water disinfection (SODIS) which involves exposing water-filled plastic polyethylene terephthalate (PET) bottles to sunlight for several hours. Exposure times vary depending on weather and climate from a minimum of fix hours to two days during fully overcast conditions.

It is recommended by the World Health Organization as a viable method for household water treatment and safe storage. Over two million people in developing countries use this method for their daily drinking water.

Solar energy may be used in a water stabilization pond to treat waste water without chemicals or electricity. A further environmental advantage is that algae grow in such ponds and consume carbon dioxide in photosynthesis, although algae may produce toxic chemicals that make the water unusable.

9. Essay on Solar Cooker:

Solar cookers use sunlight for cooking, drying and pasteurization. They can be grouped into three broad categories: box cookers, panel cookers and reflector cookers. The simplest solar cooker is the box cooker first built by Horace de Saussure in 1767.

A basic box cooker consists of an insulated container with a transparent lid. It can be used effectively with partially overcast skies and will typically reach temperatures of 90-150°C. Panel cookers use a reflective panel to direct sunlight onto an insulated container and reach temperatures comparable to box cookers.

Box Type Solar Cookers:

The box type solar cookers with a single reflecting mirror are the most popular in India. These cookers have proved immensely popular in rural areas where women spend considerable time for collecting firewood. A family size solar cooker is sufficient for 4 to 5 members and saves about 3 to 4 cylinders of LPG every year. The life of this cooker is upto 15 years.

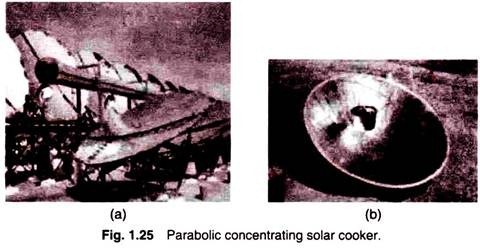

Parabolic concentrating solar cooker: A parabolic solar concentrator comprises of sturdy Fibre Reinforced Plastic (FRP) shell lined with Stainless Steel (SS) reflector foil or aluminised polyester film. It can accommodate a cooking vessel at its focal point.

This cooker is designed to direct the solar heat to a secondary reflector inside the kitchen, which focuses the heat to the bottom of a cooking pot. It is also possible to actually fry, bake and roast food. This system generates 500 kg of steam, which is enough to cook two meals for 500 people.

Positioning of solar panels or collectors can greatly influence the system output, efficiency and payback. Tilting mechanisms provided to the collectors need to be adjusted according to seasons (summer and winter) to maximise the collector efficiency.

The period four to five hours in late morning and early afternoon (between 9 am to 3 pm) is commonly called the ‘Solar Window’. During this time 80% of the total collectable energy for the day falls on a solar collector. Therefore, the collector should be free from shade during this solar window throughout the year – Shading, may arise from buildings or trees to the south of the location.

Reflector cookers use various concentrating geometries (dish, trough, Fresnel mirrors) to focus light on a cooking container. These cookers reach temperatures of 315°C and above but require direct light to function properly and must be repositioned to track the Sun.

The solar bowl is a concentrating technology employed by the solar kitchen in Auroville, Pondicherry, India, where a stationary spherical reflector focuses light along a line perpendicular to the sphere’s interior surface, and a computer control system moves the receiver to intersect this line. Steam is produced in the receiver at temperatures reaching 150°C and then used for process heat in the kitchen.

A reflector developed by Wolfgang Scheffler in 1986 is used in many solar kitchens. Scheffler reflectors are flexible parabolic dishes that combine aspects of trough and power tower concentrators. Polar tracking is used to follow the Sim’s daily course and the curvature of the reflector is adjusted for seasonal variations in the incident angle of sunlight.

These reflectors can reach temperatures of 450-650°C and have a fixed focal point, which simplifies cooking. The world’s largest Scheffler reflector system in Abu Road, Rajasthan, India is capable of cooking up to 35,000 meals a day. As of 2008, over 2,000 large Scheffler cookers had been built worldwide.

10. Essay on Process Heat using Solar Energy:

Solar concentrating technologies such as parabolic dish, trough and Scheffler reflectors can provide process heat for commercial and industrial applications. The first commercial system was the Solar Total Energy Project (STEP) in Shenandoah, Georgia, USA where a field of 114 parabolic dishes provided 50% of the process heating, air conditioning and electrical requirements for a clothing factory.

This grid-connected cogeneration system provided 400 kW of electricity plus thermal energy in the form of 401 kW steam and 468 kW chilled water and had a one hour peak load thermal storage.

Evaporation ponds are shallow pools that concentrate dissolved solids through evaporation. The use of evaporation ponds to obtain salt from sea water is one of the oldest applications of solar energy. Modern uses include concentrating brine solutions used in leach mining and removing dissolved solids from waste streams.

Clothes lines, clotheshorses and clothes racks dry clothes through evaporation by wind and sunlight without consuming electricity or gas.

Unglazed transpired collectors (UTC) are perforated sun-facing walls used for preheating ventilation air. UTCs can arise the incoming air temperature up to 22°C and deliver outlet temperatures of 45-60°C. The short payback period of transpired collectors (3 to 12 years) makes them a more cost-effective alternative than glazed collection systems.

As of 2003, over 80 systems with a combined collector area of 35,000 m had been installed worldwide, including an 860 m collector in Costa Rica used for drying coffee beans and a 1,300 m collector in Coimbatore, India used for drying marigolds.

11. Essay on Solar Chemical:

Solar chemical processes use solar energy to drive chemical reactions. These processes offset energy that would otherwise come from an alternate source and can convert solar energy into storable and transportable fuels. Solar induced chemical reactions can be divided into thermochemical or photochemical.

Hydrogen production technologies were a significant area of solar chemical research since the 1970s. Aside from electrolysis driven by photovoltaic or photochemical cells, several thermo chemical processes have also been explored.

One such route uses concentrators to split water into oxygen and hydrogen at high temperatures (2300-2600°C). Another approach uses the heat from solar concentrators to drive the steam reformation of natural gas thereby increasing the overall hydrogen yield compared to conventional reforming methods.

Thermo chemical cycles characterized by the decomposition and regeneration of reactants present another avenue for hydrogen production. A photo galvanic device is a type of battery in which the cell solution (or equivalent) forms energy-rich chemical intermediates when illuminated.

These energy-rich intermediates can potentially be stored and subsequently reacted at the electrodes to produce an electric potential. The ferric-thiamine chemical cell is an example of this technology.

Photo electrochemical cells or PECs consist of a semiconductor, typically titanium dioxide or related titanates, immersed in an electrolyte. When the semiconductor is illuminated an electrical potential develops. There are two types of photo electrochemical cells photoelectric cells that convert light into electricity and photochemical cells that use light to drive chemical reactions such as electrolysis.

A combination thermal/photochemical cell has also been proposed. The Stanford PETE process uses solar thermal energy to raise the temperature of a thermionic metal to about 800°C to increase the rate of production of electricity to electrolyze atmospheric CO2 down to carbon or carbon monoxide which can then be used for fuel production and the waste heat can be used as well.

12. Essay on Solar Vehicles:

Development of a solar powered car has been an engineering goal since the 1980s. The world solar challenge is a biannual solar-powered car race, where teams from universities and enterprises compete over 3,021 kilometres (1,877 mi) across central Australia from Darwin to Adelaide.

In 1987, when it was founded, the winner’s average speed was 67 kilometres per hour (42 mph) and by 2007 the winner’s average speed had improved to 90.87 kilometres per hour (56.46 mph).

The North American Solar Challenge and the planned South African Solar Challenge are comparable competitions that reflect an international interest in the engineering and development of solar powered vehicles. Some vehicles use solar panels for auxiliary power, such as for air conditioning, keep the interior cool, thus reducing fuel consumption.