ADVERTISEMENTS:

Here is a compilation of essays on ‘Energy Conservation in Industrial Sector’ for class 8, 9, 10, 11 and 12. Find paragraphs, long and short essays on ‘Energy Conservation in Industrial Sector’ especially written for school and college students.

Essay on Energy Conservation in Industrial Sector

Essay Contents:

- Essay on the Introduction to Energy Conservation in Industrial Sector

- Essay on the Policy Recommendations for Energy Conservation in Industrial Sector

- Essay on the Barriers to Energy Conservation in Industrial Sector

- Essay on the Case Studies of Energy Conservation in Industrial Process

ADVERTISEMENTS:

Essay # 1. Introduction to Energy Conservation in Industrial Sector:

The industrial sector is a major energy-consuming sector in India and uses about 50% of the total commercial energy available in the country. Of the commercial sources of energy, coal and lignite account for about 56%, oil and natural gas around 40%, hydro-electric power about 3% and nuclear power accounting for 1%. The level of energy consumption is very high.

In general, the Indian industry is highly energy-intensive and energy efficiency is well below that of other industrialized countries. Efforts to promote energy conservation by such industries could lead to substantial reduction in cost of production, making them more competitive globally. A comparison of energy use in some of the energy-intensive industries in India and their counterparts in developed countries is shown in Table 5.1.

There is substantial scope to improve the end-use energy efficiency of the Indian industry. It has been estimated that the total conservation potential of the Indian industry is around 25% of the total energy used by this sector.

ADVERTISEMENTS:

It is also estimated that over 5% to 10% saving is possible simply by better house-keeping and another 10-15% with small investments towards low-cost retrofitting, use of energy-efficient devices and controls, etc. The quantum of saving is much higher if high cost measures like major retrofitting, process modifications, etc., are considered.

Essay # 2. Policy Recommendations for Energy Conservation in Industrial Sector:

The Government of India has, from time to time, constituted expert groups to examine specific aspects of energy supply and demand and recommend appropriate policy measures. In the work of the earlier government-appointed committees, the emphasis, understandably, was more on aspects of energy supply.

ADVERTISEMENTS:

However, in the more recently constituted expert groups (Iner-Ministerial Working Group, Working Group on Energy Policy, Committee on Power and Advisory Board on Energy), considerable attention has been given to the conservation aspects as there is a growing realization that energy conservation can be considered as an alternate source of energy.

Some of the important policy measures recommended by the expert groups are given below:

(i) Technical and operational measures:

i. Detailed energy audits should be carried out in at least all large- and medium-sized industries.

ii. Measures to improve the efficiency of energy utilization in industries should be the most important element of energy policy in the industrial sector. Standards for fuel efficiency for each type of industry should be fixed with gradual improvement in efficiency over time.

iii. Cogeneration policies in existing industries should be identified and pursued if necessary by providing financial incentives.

(ii) Fiscal and economic measures:

i. Investments and subsidies for energy conservation schemes should be provided by creating an energy conservation fund by levying energy conservation cess on industrial consumption of petroleum products, coal and electricity.

ii. Customs duty relief on both components and equipment related to energy conservation should be offered.

ADVERTISEMENTS:

(iii) Energy pricing:

i. Energy pricing policies must ensure that:

(1) Sufficient surplus is generated to finance the energy sector investments;

(2) Economy in energy use is induced; and

(3) Desirable inter-fuel substitution is encouraged.

ii. Penal levies on industries that exceed the laid down norms and fiscal incentives for those who improve on them should be considered.

(iv) Industrial licensing, production and growth:

i. Before licences are given to new units, the capacities of the existing units and the capacity utilization factors for these units should be taken into consideration.

ii. In setting up new industries, the technologies used should be the least energy-intensive option.

iii. The possibility of utilizing waste heat from power plants, especially the super thermal stations, by setting up appropriate industries in the vicinity should be seriously considered.

(v) Organizational measures:

In large- and medium-sized industries, it must be made mandatory to appoint energy managers. In small-scale industries, a mechanism of energy auditing, reporting and improvement in energy use should be instituted.

(vi) Energy equipment:

i. Better standards must be set for energy-consuming equipment.

ii. Restrictions must be placed on the production and sale of low-efficiency equipment.

iii. Manufacture of sophisticated instruments required for monitoring energy flows must be encouraged. Import of such instruments and spare parts should be free of customs duty.

(vii) Research and development:

i. Every major industrial process should be reviewed to identify the R&D efforts required to reduce energy consumption.

ii. The Government as a distinct component of the science and technology plan should sponsor R&D programmes in energy conservation technologies.

(viii) Other measures:

i. Formal training courses for developing energy conservation expertise should be introduced in various technical institutions to maintain a steady flow of experts in the field.

ii. A system of governmental recognition and awards should be instituted for honouring individuals and organizations for outstanding performance in energy conservation.

iii. Pamphlets in local languages, suitable documentary films and programmes on radio and television should be introduced to create energy conservation awareness. While some of the measures recommended above have already been implemented, there are many where no decisions have been taken so far.

One hopes that the recommended initiatives get the attention of the policy makers and is taken note of while formulating the energy conservation bill that the Government is planning to introduce.

Essay # 3. Barriers to Energy Conservation in Industrial Sector:

While the technical and economic viability of improving the energy efficiency in India is quite substantial, there also exists a set of barriers that restrict the actual realization of this potential. The sector, in spite of being relatively organized, is highly disparate and dispersed, consisting of a large number of small manufacturing units. Although there has been a gradual improvement in the specific energy use by the industrial sector, the energy conservation move has not acquired the desired momentum.

Some key factors responsible for this are listed below:

i. Conflict of investment priority between energy conservation projects and capacity expansion.

ii. Importance given by many towards initial cost minimization, disregarding the more efficient options (which generally are more expensive).

iii. Existence of limited competitive pressure of reduce cost because of the growing economy.

iv. Shortage of capital to fund energy conservation projects.

v. Shortage of skilled staff and lack of knowledge/information on technological options.

vi. No check on manufacture and marketing of cheaper inefficient products.

Fiscal incentives:

In order to motivate the industrial sector to take up energy conservation seriously, the Government, from time to time, introduced fiscal incentives that ranged from offering 100% depreciation allowance to cut on import duties for specific items to offering energy audit subsidy schemes through various agencies. Effective from April 1983, a 100% depreciation allowance has been allowed on certain energy-saving devices and systems.

These can be categorized as:

i. Specialized boilers and furnaces,

ii. Instrumentation and monitoring systems for monitoring energy flows,.

iii. Waste-heat recovery equipment and cogeneration systems, and

iv. Power factor correcting devices.

Specified imported equipment (both energy-efficiency equipment as well as instruments to monitor energy flows) are fully exempt from the customs duty.

Essay # 4. Case Studies of Energy Conservation in Industrial Process:

In the previous section, we have studied the various options and methods of energy conservation in various equipment and systems in industries. These options of energy conservation, when implemented, can save huge amount of energy.

To demonstrate the amount of energy saved by implementing some of above mentioned energy conservation options, two case studies involving water pump and blowers are given in this section. We see that by just using the variable frequency drives in these systems, huge amount of energy is saved. This energy saving opportunity when implemented in larger context, will save substantial amount of energy.

The detail of these two case studies is as follows:

Case Study I.

Energy saving for water pump:

Application:

Transfer of hot return water from reheating furnace to the cooling tower fans.

Motors employed:

3-phase AC induction motors:

1. 37 kW, 415 V, 1460 rpm = 2 nos

2. 22 kW, 415 V, 1440 rpm = 1 no

Previous system:

1. Star delta starter for motor operation.

2. Flange coupling for operating the centrifugal pumps.

Observations:

1. One centrifugal pump was being operated with 60% outlet valve opening.

2. Cooling tower tank level was not maintained with the operation of sing e pump.

3. Second pump was being operated to maintain to tank level for short intervals. It was operated approx 40 times in 24 hrs.

4. Sometimes, second pump was being operated with by-pass valve half open to drain tank to avoid the over flow of cooling tower tank.

Process study and experimentation:

i. Pump was operated at full capacity to realize the increased flow to cooling tower. Motor got overloaded.

ii. Observations were done physically about tank levels with one pump in operation.

iii. Psychological fear of lower water level was taken and range of water level was given.

iv. It was observed that the standby pump needs to operated only 6 to 7 times in a day (24 hrs).

v. Further low and high level switch was installed with an Alarm and indicator to take care of manual labour and manpower wastage.

vi. To utilize the motor power effectively a VFD was installed and operated at 30 Hz frequency. The pump RPM takes as 900 and outlet valve was operated fully.

vii. Power consumption reduced from 32 kW to 16 kW.

Merits of new system:

1. Mechanical and electrical stresses during starts of the motor reduced to negligible. Hence the life of the equipment increased.

2. Presence of a supervisor or monitoring of the level got avoided. Hence the manpower cost reduced.

3. System power consumption reduced.

4. No churning of water in the pump and hence increases life of impeller.

Cost benefit analysis:

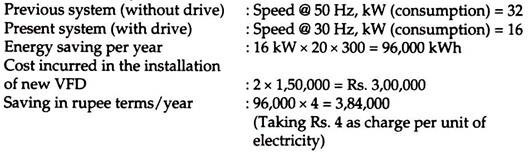

Pay-back period – Approx. 10 months

Case Study II.

Energy saving for fume exhaust system blower in cold rolling mill:

Motor rating: 3-ph AC induction motor of 50 HP, 415 V, 1460 RPM

Previous system:

1. Star delta starter for motor operation.

2. Belt pulley system for power transmission to fan.

Observation:

1. Blower fan kept working continuously at a constant speed.

2. Blower fan working at full speed irrespective of fumes generated or not at rolling mill.

Process study and experimentation:

1. Fume generation was very low during first pass rolling.

2. No fumes generation during coil handling.

3. Actual rolling duration at full and hence maximum fume generation takes place only 60% of the total duration of mill operation.

4. Manual control of inlet valve of blower fan was impractical.

Present system:

1. AC electronics speed variable drive installed.

2. Drive operation studied and software designed accordingly, optimise the power consumption during idling of mill.

3. Further optimisation done to reduce the power consumption in accordance with fumes generation.

Merits of new system:

1. Smooth start resulting in increased life of motor and mechanical system.

2. Energy saving due to speed/voltage variation during idling of the mill.

Cost benefit analysis: